Media kit

More and more automotive manufacturers are introducing BEVs (battery electric vehicles) and PHEVs (plug-in hybrid electric vehicles) into the automotive market. However, the technological and commercial competitiveness of batteries is one of the main challenges that must be overcome if millions of EVs are to be launched in the near to mid-term. The main aim of the SAFELiMOVE-project is to meet the requirements of (future) BEV users like faster charging and longer battery cycle life. This will make possible to promote electromobility and will also have a direct impact on climate change scenarios.

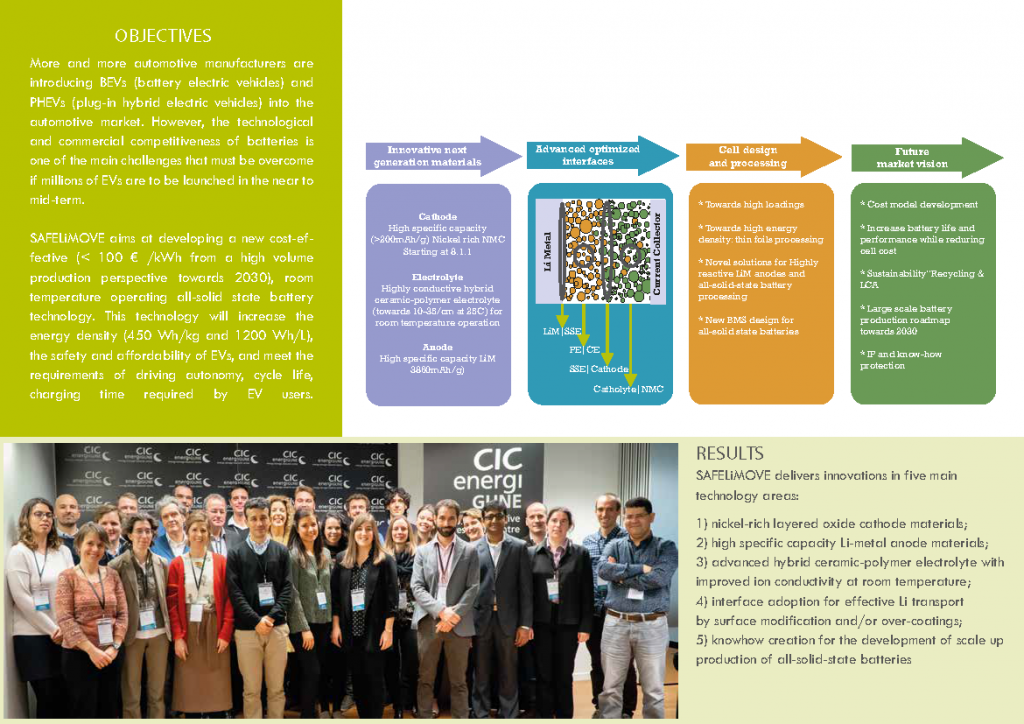

To facilitate this, SAFELiMOVE will develop a new solid-state-based technology to produce a safe, reliable and high performing battery. SAFELiMOVE delivers innovations in five technology areas:

- development of nickel-rich layered oxide cathode materials;

- high specific capacity, lithium metal anode materials;

- advanced hybrid ceramic-polymer electrolyte with improved ion conductivity at room temperature;

- interface adoption for effective Li transport by surface modification and/or over-coatings;

- and knowhow creation for the development of scale up production of all-solid-state batteries.

Through these innovations, the batteries developed within the framework of SAFELiMOVE will be of a higher energy density of 450 Wh/kg, will allow for faster charging and will have a longer cycle life.

SAFELiMOVE gathers key European actors in the battery sector, from industrial materials producers, to R&D centers and automotive industry, covering the complete knowledge and value chain. SAFELiMOVE will not only strengthen the R&D in the energy and automotive sectors but especially

Large, high-resolution images