December 2022

Intermediate result from partner: TUB with materials supply from CICe, SCHOTT, UMICORE and CIDETEC.

The general goal of High Throughput Testing (HTT) in the SAFELiMOVE project on full solid-state batteries arrays for the screening of material and process variations is to accelerate research and increase experimental confidence.

The HTT method based on area arrays of full electrochemical cells developed at TUB and Fraunhofer IZM for liquid electrolytes had to be adapted to solid-state electrolytes to speed up materials research and increase the statistical confidence. This method requires only minimal amounts of material.

HTT

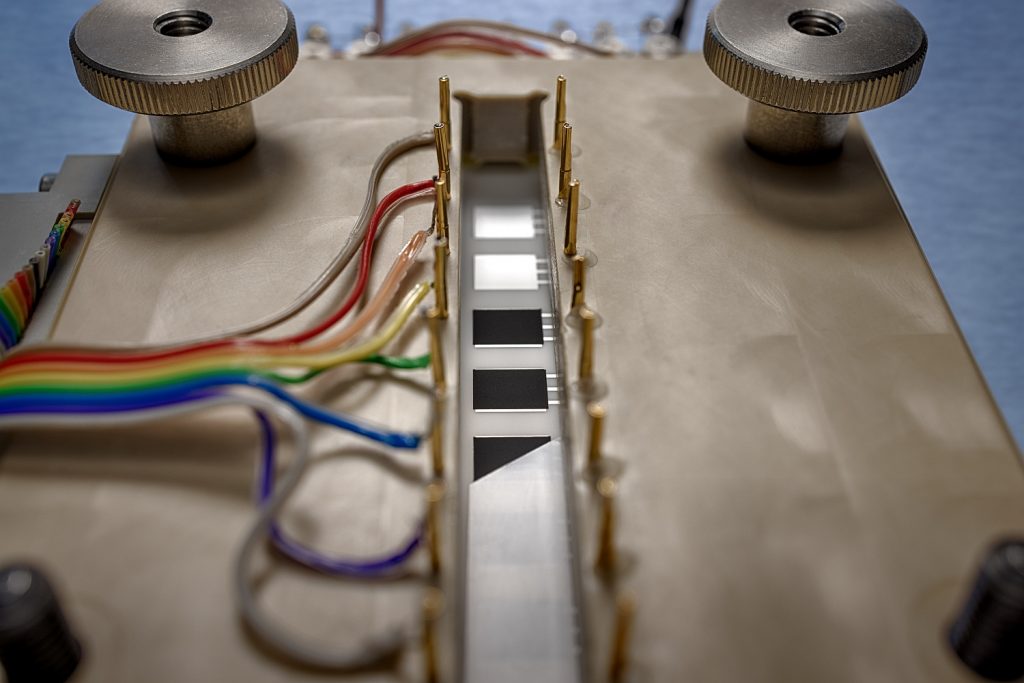

High throughput test (HTT) cell design is the approach to simultaneously screen cathode and binder materials in combination with appropriate solid state ion conductor membranes. In this method, arrays of 8 to 32 cells are arranged on a planar substrate as an array that is electrically connected to a multi-channel test system. For the cell array substrate various metals like (aluminum, nickel, copper, and gold) can be used as a current collector. Substrate materials can be glass or ceramic. This method is beneficial to speed up battery materials research and gain insightful results.

The 8 cells substrate is coated with various electrode compositions of NMC811 through automated ink dispenser needles. On the top, a thin film of the solid-state electrolyte membrane is applied, and thin lithium metal foil serves as the anode. A pre-defined testing protocol is used for the screening of NMC811 materials. HTT screening experiments were conducted at 60⁰C, where materials selection and most relevant electrochemical measurement were conducted as defined within the framework of SAFELiMOVE. After careful analysis of data, the optimized results of the material, binder and catholyte screening is forwarded to the respective domain, where after further optimization can be used for upscaling.

- Objective: HTT aims to screen and optimize the battery research materials developed within the project.

- Research: Various generation battery cathode materials(NMC811), binders, and catholyte had been screened and optimized to get the good results.

- Result: After evaluation of data, PVDF-HFP as a binder and NMC811 generation 1 material deliver more capacity and had low degradation.

- What will it be used for: – Results will be forwarded to the respective work packages, where it can be used for further optimization and upscaling.

- Impact: The research activities at TUB help to selectively choose the best materials for future research.

A deliverable has been submitted to the European Commission early 2023. Please read the public summary here.

Images: Copyright TU Berlin

Photographer: Volker Mai