February 2023

Intermediate result from partner: SAFT, CIDETEC, IKERLAN, HYDRO-QUEBEC

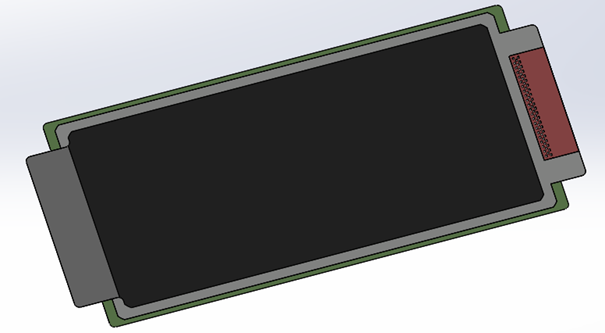

All Solid-State technology involves development of new cell design and processing methodology to achieve low interfacial resistance towards low cell impedance and optimal electrochemical performance along the battery life cycle. Saft has developed a 10Ah pouch cell in a pre-industrial prototype format to be then tested by partners for TRL6 demonstration at the end of this project. With all the feedback from processing and assembly know-how on 1st generation of small scale 1Ah pouch cell developed by CIDETEC, SAFT has designed the Final 10Ah prototype pouch cell according to the specification of LiM anode, high voltage NMC cathode, and Solid Electrolyte membrane characteristics.

- Objective: Define the design of the SAFELIMOVE large pouch cell to target a capacity of ~10Ah. Develop and optimize this All Solid-State large pouch cell for prototype manufacturing, involving new processing protocols of handling, stacking, assembly and connection welding of multiple thin electrodes.

- Research: SAFT’s team was focus on up-scaling the pouch design toward 10Ah cell and related assembly conditions of very thin and sticky layers, using LiM provided by Hydro-Quebec for anode, high loading cathode by CIDETEC and Solid Electrolyte membrane upscaled by SAFT. This new cell design made in SAFT required multiple processability tests achieved with SAFELIMOVE materials samples. Tab welding was investigated especially for bonding to very thin LiM anodes. A good electrolytic contact between all electrodes and solid electrolyte layers require specific smoothing operation. The cell pressure holding has been set to ensure intimate contact of the different components despite the thickness variation due to Lithium transport across cycles.

- Result: The feasibility of this multilayer Pouch cell design has been confirmed with its related prototyping assembly flowchart, using new specifically designed tools. Detailed definition of each component and assembly conditions have been set. Innovative solutions have been developed for handling and stacking these sticky membranes with anodes, as well as the tab connection by welding with multiple LiM layers.

- What will it be used for: These large pouch cells will be manufactured by SAFT and delivered to partners for electrical performances, life and safety tests. 6 cells will be integrated in a 24V battery demo module developed by IKERLAN.

- Impact: It will demonstrate that the materials developed can be used to manufacture pouch cells at large scale in a pre-industrial environment. The assembly of ~10Ah prototypes will provide an important input on all the production chain of solid-state batteries. From this experience, key issues during SSB manufacturing process will be identified and solutions for large-scale production will be proposed.

Read the public summary of the report here